How do I Know what swimming pool pump is right for you?

Contrary to the advice given when selecting a filter, a bigger pump is not always a good thing. Unless you have been advised by a pool professional, or someone in the know that your existing pump was undersized, it would be wise to keep the same horsepower as you have now.

How do I know what Horsepower my pump motor is?

The horsepower should be listed on the nameplate (justify) of the pump motor (in very tiny letters – hp). If the motor nameplate is burnt or worn off, sometimes a part number of the impeller (right) can tell us which hp your pump motor is. MagneTek Impeller Name Plate Example to see Part Number; Nameplate of an A.O. Smith Copr. Motor, 115/ 230 Volts, 1/2 HP, Phase 1, 8.8/ 4.4 Amps. If the existing pump has done you well, it is easiest to plumb and wire with the exact same pump. The heights and lengths are the same, which makes the job a bit simpler.

Are all of the pumps the same?

All of the manufacturers of pumps represented are Major Manufacturers; well respected, very large, international market leaders. The motors used on the pumps are all nearly the same. There has not been any really astounding inventions in pump technology in the last few years, so all innovations have been implemented by most in one way or another. Each pump is slightly different in its hydraulics, shape, basket and lid, and colors. But these may or may not matter a whole lot. Read on for more substantial ways to discern between pumps.

You will find that there are low head pumps for aboveground pools and medium and high head pumps for inground pools. “head” refers to the flow rate, in a backwards kind of way.

– Aboveground filter systems and small inground pools (under 10,000 gals) should use a Low Head pump like a Maxim, or Dynamo or Power-Flo.

– Pools from 10,000-20,000 gals can use a Medium Head pump like a SuperPump, a Pinnacle or Cygnet.

– Pools over 20,000 gals could possibly use the High Head pumps like, Super II, Challenger, Ultra-Flo or the Sta-Rite pumps.

– Pool/ Spa combos with at least 3 lines influent and 2 – 3 back to the pool, 2″ plumbing may be able to handle the Ultra High Head pumps like NorthStar and the WhisperFlo.

Remember to match hp and pump type and flow rate. Use the Flow Rate Charts, (see below) based on a sample feet of head (vertical axis) of 40 or 50 feet. This is the only true way to compare pump to pump.

Whisperflo Flow ChartAs Americans, it’s natural to want the big V8 power plant, but a pump that is too powerful could actually prevent filtration while damaging the filter and heater. Pipes or fittings could even be blown apart. When matching pumps to filters, check the Design Flow Rate of the filter from the nameplate. The average flow for the pump you select, should be within 10% of the filter’s Design Flow Rate.

Remember also, that a smaller hp motor is going to draw fewer amps, which is going to cost less to operate. If you are careful to match up flow charts, you could actually reduce the hp required, while increasing the head of the pump. For instance, a 3/4 hp Whisperflo produces the same amount of flow as a 1 1/2 hp SuperPump. So, you could replace one with the other, while electrical costs are nearly cut in half!

So, when selecting a pump, keep it close to the original specifications, and use the Flow Charts. Most systems could handle a small increase in pump size, especially if you are replacing the filter with a larger one.

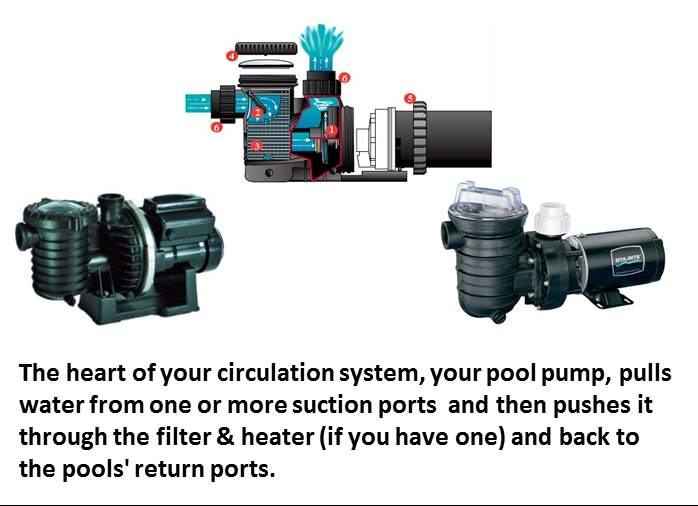

The water is moved by a brass or plastic impeller that is shaft driven by an electric motor. On the way to the pump, the water is under suction or vacuum. After the impeller, the water is now under pressure until it is released into the pool. The 3/4 – 2.0 hp motor is powered from a breaker on your electric panel (or fuse box), at 115 or 230 volts. Usually motors over 2 hp need 230V power to operate, and most smaller Hp pumps convert to accept either 115 or 230 volts. Above ground units may plug into an 115V GFCI outlet. (Be sure to buy a Pump that will match the correct voltage going to your existing power supply). Electrical consumption will vary by area, however, manufacturers have been designing motors and pumps (the wet end) which are more efficient and consume much less energy than older pumps. The smaller the Amp draw of the motor, the less expensive it will be to operate.

How long do motors last?

Motors typically last an average of eight years before needing either rebuilding or replacing. Noisy, screeching front and/ or rear bearings will let you know when you need to do something.

Pump Troubleshooting Guide – This easy to read guide will help you with some of the most common problems that occur with pumps.

Leaking pump?

A very common problem is the threaded fitting carrying water out of the pump shrinking and allowing water to drip, run and then spray. This can be replaced with a high temp fitting to prevent its re-occurrence. Approximately $10 parts and one hour labor. Water may also leak from a worn out mechanical seal. This seal is the separation between the wet end and the dry end (motor) of the pump. This mechanical shaft seal should be replaced. Approximately $12 for the seal and one hour labor.

Air in pump basket?

The pump is meant to operate air free. After some time, you may notice air in the basket, especially if you have a clear lid to observe such things. This can reduce filtering efficiency, allow dangerous air to build up in filter, and sometimes prevent your pump from catching prime (being able to move water). The problem is usually located around the pump, above-ground. Occasionally, we have to look underground for the source of the air. Approximately 1 – 4 hours labor. Sometimes air in the pump basket can be caused by something as simple as the water level being too low in the pool. You might also want to check the skimmer weir. This is a plastic flap at the throat of the skimmer that keeps the debris in the skimmer when the pump is off. If the skimmer weir is stuck it can cause the skimmer to drain and take in air. Also check that the pump basket lid is on tight and the o-ring is lubricated.

Pump is not pumping water like usual?

Check your skimmer baskets for heavy debris. Make sure the pump basket is clean and properly positioned. Some types of pumps have a pump strainer basket that locks into place to prevent the basket from floating and causing the pump to starve for water. Sometimes when we get repair calls like this we’ll find that the pump basket is cracked and it is allowing debris to clog the pump’s impeller. If the pump basket is cracked or damaged, it should be replaced. To check the impeller, turn off the motor, remove the pump basket and reach into the volute and feel if it is clogged with debris. If you cannot feel for sure, you may need to remove the motor from the pump to properly inspect the impeller. Many times you need only remove a clamp band to separate the motor from the pump.

Noisy Motor?

Inside of your pump’s motor are a front bearing and a rear bearing. These bearings are sealed and cannot be re-packed or re-lubricated. They are replaced when they begin to scream and screech. Bearings can become damaged when the pump has run dry and overheated, or if the pump is put under high loads. A local motor shop can replace the bearings for you, usually for under $100. One test I do is to remove the motor from the pump, and turn it on. If it still screeches (while not pumping anything) it is going to be the bearings. Rebuild it, or better yet, just replace the motor. A noisy pump can also mean cavitation. This sounds less like screeching and more like grinding. This condition is caused by starving the pump for water. If possible, open more valves, or find the cause of the obstruction that is blocking water flow into the pump. It may be the impeller. Finally, noisy pumps can be the sound of components striking one another. The impeller can, on stub shaft models, come loose, and hit against the impeller housing. The internal fan can break and hit against the motor side. Both instances will resolve themselves. At 3450 rpm, it won’t take long for the fan to wear down or the impeller to chew right through the housing. These conditions are rare, and probably will require a new pump.

– Motor will not start or turn on:

First check that you have power. Is the breaker on? Time-clock on? All switches on? Use an electric meter to be sure that voltage is correct. Check that all electrical connections are tight and not corroded or shorted out by bugs or debris. Again, the use of a meter or test lamp will check this with certainty. If there is power going all the way to the motor, the motor may have become shorted across its windings.

– Motor hums but will not start:

The impeller may be clogged with debris. Turn off the power, and spin the impeller shaft. If it won’t turn freely, remove the motor from the pump and clean the impeller. If it does spin, check the capacitor. If it is a stub shaft type motor, check that the impeller is not hitting the impeller housing.

The capacitor is the black cylinder on the back of the motor, although sometimes it is silver and mounted on top of the motor. Check the capacitor for white residue or oily discharge or for bulging. Sometimes even a fine looking capacitor can be bad. Replace with a new capacitor of the same rating. Finally, low voltage can be a cause of a humming but not starting motor. New motors are wired 220 volts, so if you hook it up to 110 volts, it will only hum, or cycle. Or perhaps one of the power leads is loose, or shorted. Check with a Multimeter to verify the correct voltage, with a variance of 10% allowed.

Motor Cycling:

If the motor runs for a short while, shuts itself off, and turns itself back on later, it may be overheating. Normal motor temperature is over 140 degrees, so all motors run hot. But a cycling motor may indicate that the thermal overload is kicking it off. If this motor was just replaced, make sure that the electrical supply connections are correct and the wire size is correct for the voltage it is carrying. Low voltage can cause overheating. Inadequate ventilation can cause overheating, so make sure that the air vents are unobstructed. Usually, old motors that suddenly begin to overheat will need to be replaced. They usually have a short inside, across the windings. And motors are just not rewound anymore like they were in the old days.

How to INSTALL an entire new pump:

Plumbing in a new pump motor…

Cut the pipes going into the front of the existing (old) pump, and the pipe coming out of the top. Important: Choose your cut location so as to allow room on either side of the cut to glue on a repair coupling. Remove the wires and the conduit adapter from the rear of the motor. Remove the MTA fittings threaded into the front and top of the old pump. Using Teflon tape and perhaps also silicone sealant, thread in the fittings you removed from the old pump. Note: Do Not Over-tighten, turn only 1 1/2 turns past hand tight. Using rubber mission couplings, PVC unions or simple slip x slip couplings, reconnect the pipe you cut. On PVC fittings, use a good primer and good, fresh PVC glue for pressure applications.

Wiring up a new pump motor…

First, screw in the conduit adapter onto the back of the motor. This adapter is usually removed from the old pump and screwed into the 3/4″ threaded hole where the wires enter the back of the motor. Some motors offer an additional port of entry on the top for wiring flexibility. Remove the back of the motor and run the wires in through the adapter, and tighten down the threaded connector to secure the wires and keep out moisture and insects. Notice where the wires enter the back of the motor, on the right side, a terminal board that has 2 brass screws for clamping down the 2 wires (lines) coming in. It doesn’t matter which wire goes to which screw. Above the terminal board, there is a green screw that is for clamping down the ground wire.

All pump motors are wired to receive 230 Volts from the factory. That is, 2 lines (wires) carrying 115 Volts each. So, you need to know if you have 115 Volts coming in, or if it’s 230 Volts. Usually 230 Volt service will have 2 wires of the same color, (and one green ground wire), while 115 Volt service will have perhaps one red (hot), one white (neutral), and one green. You should use a meter to be sure, but you could just look at the breaker. If 2 of the wires come off of one breaker, then you have 230 Volts. If one is connected to a breaker, and the other to the ‘neutral’ Buss bar, then it is 115 Volt service. Or look at the voltage plate on the old motor and see how it was hooked up. Is it matching the Low Voltage diagram (115 Volt), or matching the high voltage diagram (230 Volt)?

If you have 230 Volt service, hook up the wires coming into the motor to the brass terminals described above. If you have 115 Volt service, follow the instructions on the motor label to switch the motor to receive 115 Volt. This is a very easy switch of only one wire. Again, the motor comes factory wired for 230 Volt. If you are connecting 115 Volts to it, then switch the motor first. Putting 230 Volts into a 115 Volt motor can damage the windings, and perhaps fail the motor. After switching the motor to 115 Volts, connect the power wires to the brass terminals as described above (again it doesn’t matter which wire goes to which screw).

Replacing the motor:

Having learned how to remove and break down a pump and motor in the previous sections, replacing any of the components is simply a matter of disassembling the pump down to the component that needs replacement, getting a replacement part, and reassembling the unit. Of course, if the entire pump and motor is to be replaced, you purchase the replacement as a unit and plumb it in as previously described. Sometimes the motor will trip the circuit breaker when you try to start it. If this happens it is usually because there is something wrong with the motor; however, it could be a bad breaker or one that is simply undersized for the job and has finally worn out. To replace the motor here is the procedure:

– Break down the unit as described in the section on changing a seal. Remove the shaft extender by removing the Allen-Head setscrews and pulling the extender off the motor shaft. Sometimes this might need persuasion. Use your large flat-blade screwdriver to pry the extender away from the motor body. Sometimes corrosion will eat away at the setscrews and extender – if it is too tough to remove, replace it.

– Before sliding the shaft extender on the new motor, clean the motor shaft with a fine emery cloth such as you might have in your copper pipe solder kit. Apply a light coat of silicone lube to the shaft. When you put the extender on the motor shaft, the setscrews go into a groove that runs along the shaft. This groove allows the screws to grip and not slide around the shaft.

– Now slide the new extender in place, lining up the setscrews along the channel, but do not tighten the setscrews. When you have reassembled the bracket and seal plate, seal, and impeller, you can adjust the impeller to just barely clear the seal plate face, then tighten the setscrews. Be sure the impeller is screwed tightly onto the shaft extender before making this adjustment. If it is loose, when the motor starts it will tighten the impeller, by turning it tighter against the extender, thereby tightening it against the seal plate, seizing up the unit.

– Secure the shaft extender with your pliers or 3/8 – inch box wrench and lay a rag over the impeller. Firmly hand tighten it. Reassemble the remaining pump parts and/or re-plumb the entire unit back into place.

Follow wiring instructions above, in previous section on installing new pumps.

Lubrication…

I always try to stress to pool owners that a lot of air in the pump or loss of prime problems are due to lack of lubrication on the pump lid o-ring. Lubricants like Magic Lube (Teflon based) or Jack’s Lube are always a great choice. Remember that a little dab will do the job. Never use a petroleum based product (i.e. Vaseline) for lubrication on o-rings. Inspect the pump o-ring for cracks, splits, or pinch marks. Finding little problems can prevent big problems from occurring.

Replacing the Mechanical Shaft Seal:

All pumps have seals to prevent water from leaking out along the motor shaft. When these wear out due to overheating, vibration or a sudden change in water pressure – you will need to replace your pump shaft seal. The first thing to do is to turn off the electricity to the motor at the breaker.

– To access this seal for replacement, remove the four bolts that hold the pump halves together, it is not necessary to remove the entire pump from the plumbing system.

– Grasp the motor and pull it and the bracket away from the pump volute. Wiggle it slightly from side to side as you pull back to help break this joint.

Replacing the Mechanical Shaft Seal:

All pumps have seals to prevent water from leaking out along the motor shaft. When these wear out due to overheating, vibration or a sudden change in water pressure – you will need to replace your pump shaft seal. The first thing to do is to turn off the electricity to the motor at the circuit breaker.

– To access this seal for replacement, remove the four bolts that hold the pump halves together, it is not necessary to remove the entire pump from the plumbing system.

– Grasp the motor and pull it and the bracket away from the pump volute. Wiggle it slightly from side to side as you pull back to help break this joint.

– Take your pliers or a wrench and hold the shaft extender to prevent it from turning. Unscrew the impeller from the shaft extender using an impeller wrench. You can also wrap a rag over the face of the impeller so you don’t cut yourself and twist it off by hand. As a last resort, hold a large screwdriver against the impeller and tap it gently with a hammer. Use care not to damage the impeller. Use even more care that the screwdriver doesn’t slip and damage you.

– Remove the four bolts that hold the bracket on the motor. If needed, use a hammer to gently tap the bracket away from the motor.

– Remove both halves of the old seal. Notice how each half is installed so you get the new one back in the same way. One half is in the back of the impeller and is easily popped out with a flat-blade screwdriver. The other half is in the seal plate and motor bracket unit. Lay the bracket on your workbench with the seal on the bottom. You will see the back of the seal through the hole in the seal plate. Using the flat-blade screwdriver once again, put the tip on the back of the seal and tap it with a hammer. It will pop out easily.

– Install the new seal. First, look up your pump in the manufacturer’s literature or supply house catalog to determine what model seal you need. Clean out the seal plate and impeller where you have just removed the old seal. Use an emery cloth or a small wire brush and water. Dry each area and apply a small amount of silicone lubricant to help the new seal slide into place. Install each half of the seal the same way you removed the old one, white ceramic of one half facing the glazed carbon ridge of the other half. Use care in installing not to damage, nick or soil the face of either seal half.

– Gaskets. When you break apart a pump, the old gasket usually won’t reseal. Clean all of the old gasket off of the seal plate and volute. Scrape it clean if needed with a flat blade screwdriver. Now reassemble the pump the same way you took it apart, placing a new gasket between the pump halves.

– Check for leaks by starting the pump and let it run several minutes. A fresh paper gasket might leak for a few minutes until it becomes wet and swells to fill all the gaps, but it should stop leaking after a short time. If your job does leak, take it apart and go over each step again, making sure the seal halves are seated all the way and that there is no corrosion or debris justify in the impeller or seal plate that might prevent the new seal from seating completely. You may add some Blue RTV silicone sealant to help a paper gasket.

In some pumps where the parts are assembled differently, you follow the same steps. The clamp is removed to disassemble the pump halves, and you must remove the diffuser to get to the impeller. To remove the impeller you can grip it with your hand and twist it off, but the trick with these units is to stop the shaft from spinning as you twist off the impeller. There are air vents in the motor on the end closest to the pump itself. Look in and you will see the motor shaft. Place a flat-blade screwdriver in one of the air vents and wedge it against the shaft to keep it from turning.

Alternatively, you can remove the end cap and look inside as you twist the impeller. You will see the back end of the shaft, with the start switch attached. Since this switch is fragile, you must remove it (one screw) to access the slotted screw in the back end of the shaft. Place the screwdriver in this screw to keep the shaft from turning as you remove the impeller. Or use a 7/16″ wrench on the back of the shaft.

Instead of a gasket, some pumps use an O-ring. Clean this and lubricate it before reassemble. If it has stretched and it seems like there is too much O-ring for the channel in the volute, try soaking the gasket in ice water for a few minutes to make it shrink a bit.

Some pumps use a plastic impeller with a housing that holds half the seal in place. If the pump has run dry and overheated the pot, this housing might be warped and the seal will not fit tightly. The only solution is to replace the impeller. This is a common problem with automatic cleaner pumps, which are not self-priming. Remember to use only non-hardening silicone lube like Magic Lube on all pool and spa work. Make Sure not to use Vaseline or other lubricants that are made of petroleum, which eat away some plastics and papers.

Clogged Impeller?

When your pressure is high, your filter is dirty, right? When your pressure is lower than normal, your pump basket is dirty. If the basket is clean, yet pressure and flow is still low or surging, you may have an air problem or the impeller may be clogged. Something prior to the filter is obstructed. To unclog an impeller follow these steps:

– Shut off power, remove motor and seal plate from pump. Sometimes this is one clamp that holds the motor to the pump, or some pumps have nuts or bolts to remove.

– Stand motor on it’s end, remove any diffuser or impeller shroud, and using needle nose pliers or a thin screwdriver, remove the clog. Run some heavy wire through the vanes of the impeller.

– Reassemble pump snugly and tightly. Fill pump pot with water. Restart pump. Pressure then should rise.

Locating an Air Leak…

Make sure the strainer lid is on tight, with a clean, lubed o-ring. Also check that all plugs are tight. A good trick in locating an air leak is to shut off the motor when it’s under full pumping head pressure, and look for water to spray back out of the void where the air was entering. You have to be quick to catch this spray-back! This void will always be before the impeller. After the impeller is what we call “the pressure side.” Any leak or void here will leak water out. Any leak or void prior to the impeller (in front of the pump impeller) will draw air in when the pump is on. The pump will “pump” air if it can, it is the path of least resistance. So, your system needs to be almost airtight to run properly. When you find this void, patch with epoxy putty or silicone, or replace the part if needed.

If that didn’t work, you can do this…buy a Drain King at your local hardware store. This connects to a garden hose and puts the line under pressure. Putting this in the skimmer, you can turn on the hose and pressurize the line backwards (Also Great for clearing clogged pipes). Remove the pump lid and use a plug at the pump entrance. This will allow pressure to build up in the line and squirt out at the leak. Many suction side leaks found in this manner are then repaired with pool putty, or a more permanent plumbing repair / pipe replacement can be made. Make sure the water level in the pool is high enough, and that the skimmer weir is not stuck in the up position. Make sure that the incoming and outgoing valves are in the open position. If you suspect a clogged line, you can purchase a Drain King at a local hardware store, or from us (just click on the link) to pressurize the line backwards from the skimmer towards the pump and remove leaf/debris obstructions.

Replacement of filter pump:

When replacing your motor, you may opt to install a high efficiency pump (one that is sized correctly for your filter). This will reduce energy consumption and/or increase skimmer suction to make the pool easier to keep clean. Prices vary, however, in the way of example, the 1 hp Hayward SuperPump will cost $299, plus a few plumbing fittings and one hour labor. There may also be electrical costs to upgrade or remove hazards.

To replace or rebuild your motor?

For most all rebuilds of your motor, expect charges of $100 to have a motor shop rebuild a motor (which you bring to them and pick up). Theoretically, the motor will last another eight years, but the warranty is only 90 days. Replacing the motor with new would cost $187 for a 1 hp AO Smith motor, plus one hour labor. The warranty on the new motor is 2 – 3 years for most manufacturers. Whether rebuilding or replacing the motor, the Mechanical Shaft Seal should also be replaced.

Booster Pumps

You may have an automatic pool cleaner (ex. a Polaris) that requires a booster pump. It looks different from your filter pump because it doesn’t have a strainer basket. All else is the same, however it should last longer if it’s being used only a few hours per day. Never operate the booster pump without the filter operating and providing it a constant flow of water. If you have time clocks, synchronize them to ensure this doesn’t happen. Otherwise, you will probably burn up the shaft seal, and possibly damage the bearings.

Blower Motors

If your pool has an attached spa, you may have a forced air blower motor sticking up above water level. This is connected into the spa jets (return lines) to provide turbulence and air therapy. If your blower motor is not working or is very noisy, it may need rebuilding or replacing. Warranties and prices are very similar to filter motors. Before calling for service on any motor, check that switches on the motor are on, breakers are on, spa side or indoor remote controls are on, and the timer is on.

Swimming Pool Pump Suppliers and Models:

Eco Pumps EP-1 to EP-8

Hayward EcoStar SVRS Safety Vacuum Release System

Hayward EcoStar Variable Speed Pumps

Hayward Max-Flo

Hayward Max-Flo II

Hayward NorthStar Pump

Hayward Super II

Hayward Super Pump

Hayward TriStar

Jandy ePump Variable Speed

Jandy FloPro

Jandy PlusHP

Jandy Stealth Pump

Pentair IntelliFlo Varible Speed Pump

Pentair SuperFlo Pumps

Pentair WhisperFlo Pumps

Speck Badu EcoM3 3-Speed

Sta- Rite Max-E-Pro Pumps